There are many types of steel plant refractory materials. According to their chemical properties, they can be divided into acidic, alkaline and neutral refractory materials. According to the use parts, they can be divided into blast furnace refractory materials, converter refractory materials, electric furnace refractory materials, etc. The following are some common steel plant refractory materials:

Acidic Refractory

Silica Brick: Mainly made of silica, it contains a large amount of silicon dioxide. It has good acid corrosion resistance, high load softening temperature and good high temperature volume stability. It is suitable for acidic furnace linings, such as blast furnaces and steelmaking furnaces. It is often used to build carbonization chambers and combustion chambers of coke ovens.

Clay Fire Brick: With refractory clay as the main raw material, its production process is relatively simple, the price is low, and it has a certain degree of refractoriness and thermal stability, but its refractoriness is relatively low. It is suitable for some parts with low temperature and weak erosion, such as the furnace wall and flue of the heating furnace.

Basic refractory materials

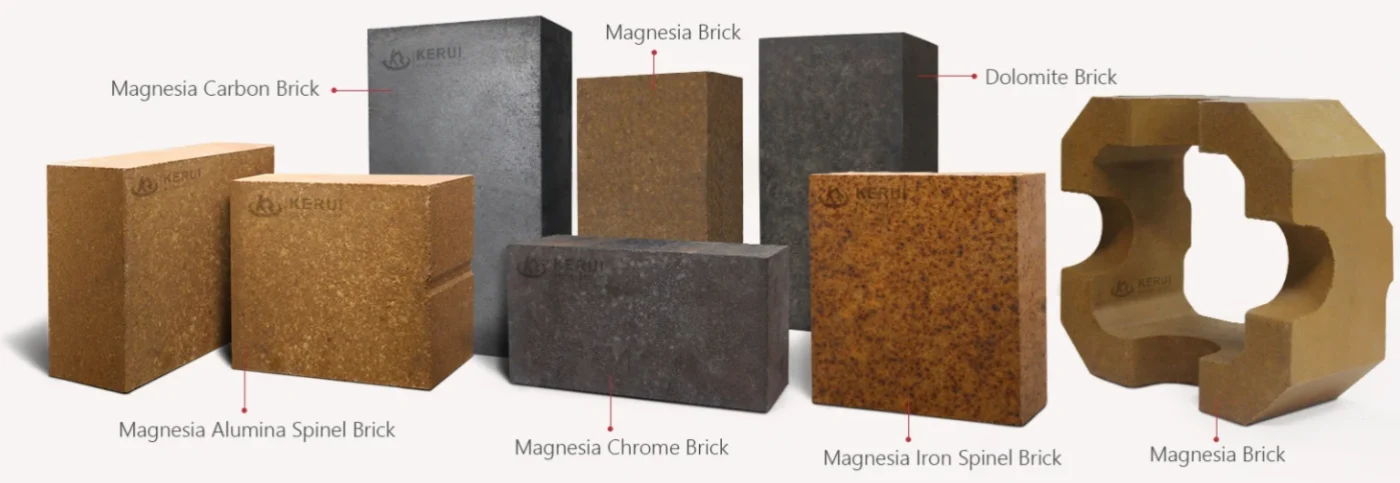

Magnesium bricks: The main component is magnesium oxide, which has high refractoriness, good corrosion resistance to iron oxides, basic slag and high calcium flux, etc. It is often used in smelting furnaces and refining furnaces of alkaline molten metals, such as steelmaking converters and electric furnace linings.

Dolomite bricks: Made by mixing dolomite and clay, the main component is magnesium calcium carbonate, which has good alkali resistance and corrosion resistance. It is suitable for alkaline furnace linings, such as steelmaking furnaces, refining furnaces, etc. In some special steelmaking processes, dolomite bricks are also used for the construction of furnace bottoms and furnace walls.

Neutral refractory materials

Chromium bricks: With chromium ore as the main raw material, it contains chromium trioxide and other components. It has the characteristics of high temperature resistance, corrosion resistance, and good thermal shock resistance. It is suitable for the lining of equipment such as steelmaking furnaces and ironmaking furnaces, such as the furnace walls and furnace roofs of electric furnaces.

Mullite brick: Mullite is the main component, with good thermal stability, high temperature strength and corrosion resistance. It is made of clay ore after high temperature sintering. The refractoriness is generally between 1200℃-1400℃. It has a wide range of uses and can be used for various furnace linings, such as heating furnaces, soaking furnaces, etc.

Special refractory materials

Carbon brick: Carbon is the main component, with extremely high thermal shock resistance, corrosion resistance and good thermal conductivity. It is suitable for blast furnaces and converters working at high temperatures. It is often used to build the bottom and hearth of blast furnaces.

Corundum brick: Alumina is the main component. It can be divided into different grades according to the different alumina content. It has high refractoriness, hardness and corrosion resistance. It is suitable for high-temperature furnaces and molten metal containers, such as the furnace cover of electric furnaces and the lining of ladles.

Silicon carbide bricks: With silicon carbide as the main raw material, it has the characteristics of high thermal conductivity, good thermal shock resistance, strong wear resistance, etc. It is suitable for use in the middle and lower parts of the furnace body, such as the middle and lower parts of the blast furnace, the furnace waist and other parts.

Insulating refractory materials

Lightweight insulating bricks: With lightweight materials such as diatomaceous earth, vermiculite, perlite, etc. as the main raw materials, it has the characteristics of low density, low thermal conductivity, good thermal insulation performance, etc. It is used for the insulation layer of the furnace to reduce heat loss and reduce energy consumption.

Ceramic fiber products: Made of ceramic fiber, it has the characteristics of high temperature resistance, low heat capacity, low thermal conductivity, good chemical stability and thermal shock resistance. It can be made into fiber blankets, fiberboards, fiber ropes and other forms for thermal insulation, sealing and heat preservation of furnaces.

KERUI Refractory can provide all the above refractory materials for steel plant. If you have related projects, our engineers will provide you with the necessary help.