Description of SK Fireclay Bricks

SK34 Firebrick is a high quality Clay refractory brick. It typically has a yellowish color and a standard cuboid shape, often with dimensions like 230×114×65mm. Classified as a Fire Clay Brick, it contains at least 30% Al₂O₃ and no more than 2% Fe₂O₃. This chemical composition gives it excellent chemical stability and resistance to slag.

我们供应 SK 系列耐火砖。根据出口标准,SK30/32/34 为粘土砖,SK36~40 为高铝砖。具体规格可根据客户要求定制。欢迎随时咨询!

Technique Data of Kerui SK Fireclay Bricks

| 项目/等级 | SK-30 | SK-32 | SK-34 | SK-35 | SK-36 | SK-38 | |

|---|---|---|---|---|---|---|---|

| Al2O3, % | ≥ | 30 | 35 | 38 | 45 | 50-55 | 65-70 |

| Fe2O3, % | ≤ | 2.5 | 2.5 | 2 | 2 | 2.5 | 2.3 |

| Refractoriness (SK) | ≥ | 30 | 32 | 34 | 35 | 36 | 37 |

| Refractoriness underload, 0.2MPa, °C | ≥ | 1250 | 1300 | 1360 | 1420 | 1450 | 1480 |

| 表观孔隙率,% | ≤ | 22-26 | 20-24 | 20-22 | 18-20 | 22 | 20 |

| Bulk Density, g/cm³ | ≥ | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 | 2.15-2.22 | 2.25-2.35 |

| 冷压强度,兆帕 | ≥ | 40 | 45 | 30 | 40 | 45 | 50 |

Note: We can also provide unconventional SK40.

Advantages of SK Fireclay Bricks

高折射率

它能承受的温度范围为 1770℃ 至 1800℃,在 0.2MPa 下的负载软化温度不低于 1360℃。因此,它适用于高温工业炉和窑炉。

良好的化学稳定性

其铝₂O₃含量不低于 38%,铁₂O₃含量不高于 2%,具有良好的化学稳定性和抗渣性。它能抵抗各种化学物质的侵蚀,确保其在恶劣化学环境中的性能和使用寿命。

低导热性

耐火砖的导热系数低,有助于有效减少热量传递。这不仅提高了窑炉的热效率,还降低了能耗和向外的热损失,起到了节能环保的作用。

机械强度高

耐火砖的导热系数低,有助于有效减少热量传递。这不仅提高了窑炉的热效率,还降低了能耗和向外的热损失,起到了节能环保的作用。

出色的体积稳定性

SK34 耐火砖在高温下的蠕变率很低,这意味着它具有良好的体积稳定性。在长期高温使用过程中,它能保持原有的形状和尺寸,降低了因砖块变形而导致炉子损坏的风险。

Application of SK Fireclay Bricks

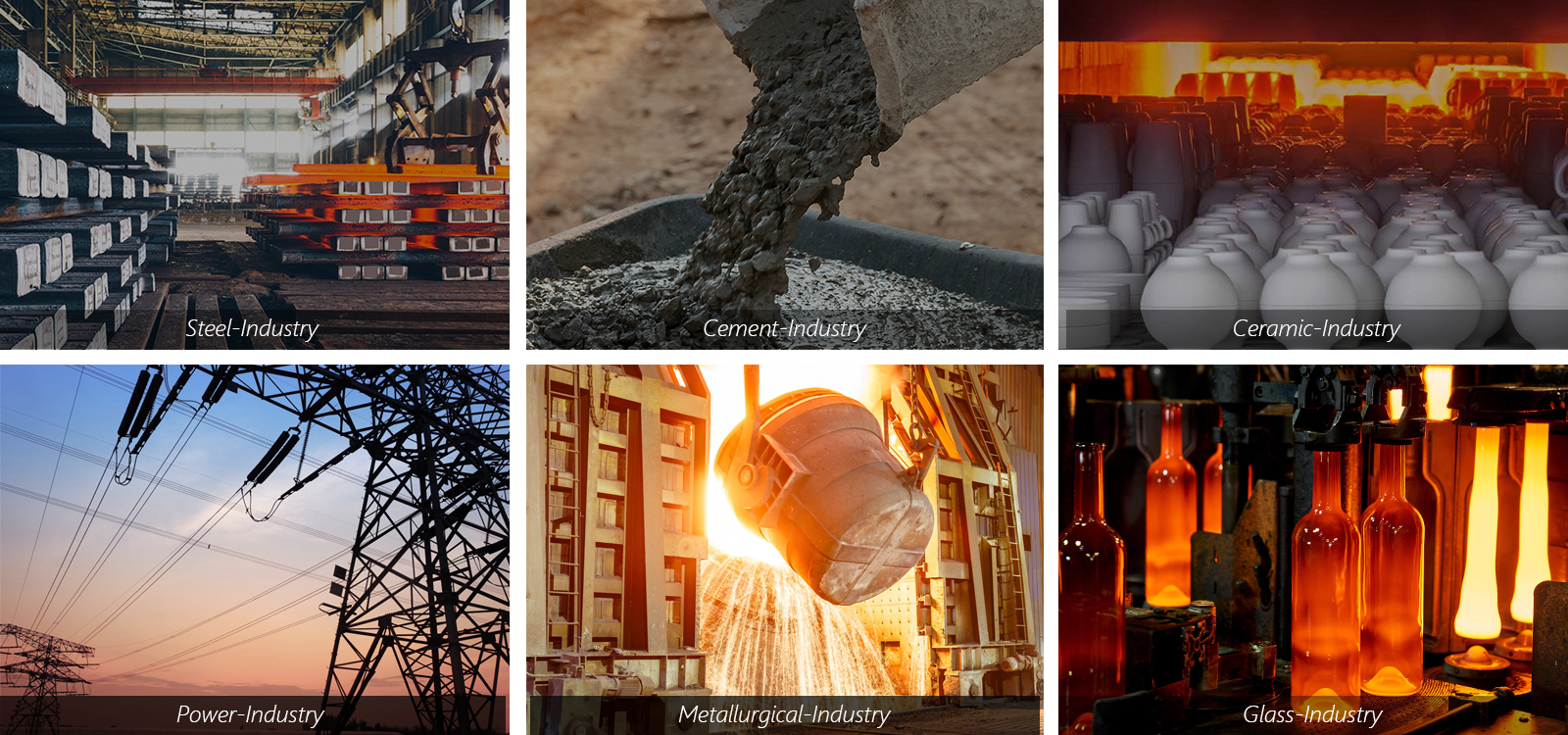

SK Fireclay Bricks is widely used in various high – temperature industrial applications. It is commonly employed in metallurgical furnaces, such as blast furnaces and steel – making furnaces. It is also used in ceramic kilns and glass – melting furnaces, where it helps to withstand high temperatures and protect the furnace structure.