·

·Fused Magnesium

Fused Magnesium (FM) is a type of refractory material that is produced by the electric arc melting of caustic calcined magnesia, deadburned magnesia or raw magnesite in furnaces at temperatures in excess of 2750°C.

- w(MgO)≥/%: 94-98

- w(SiO2)≤/%: 0.5-2.5

- w(AL2O3)≤/%: 0.15-0.6

Description of Fused Magnesium

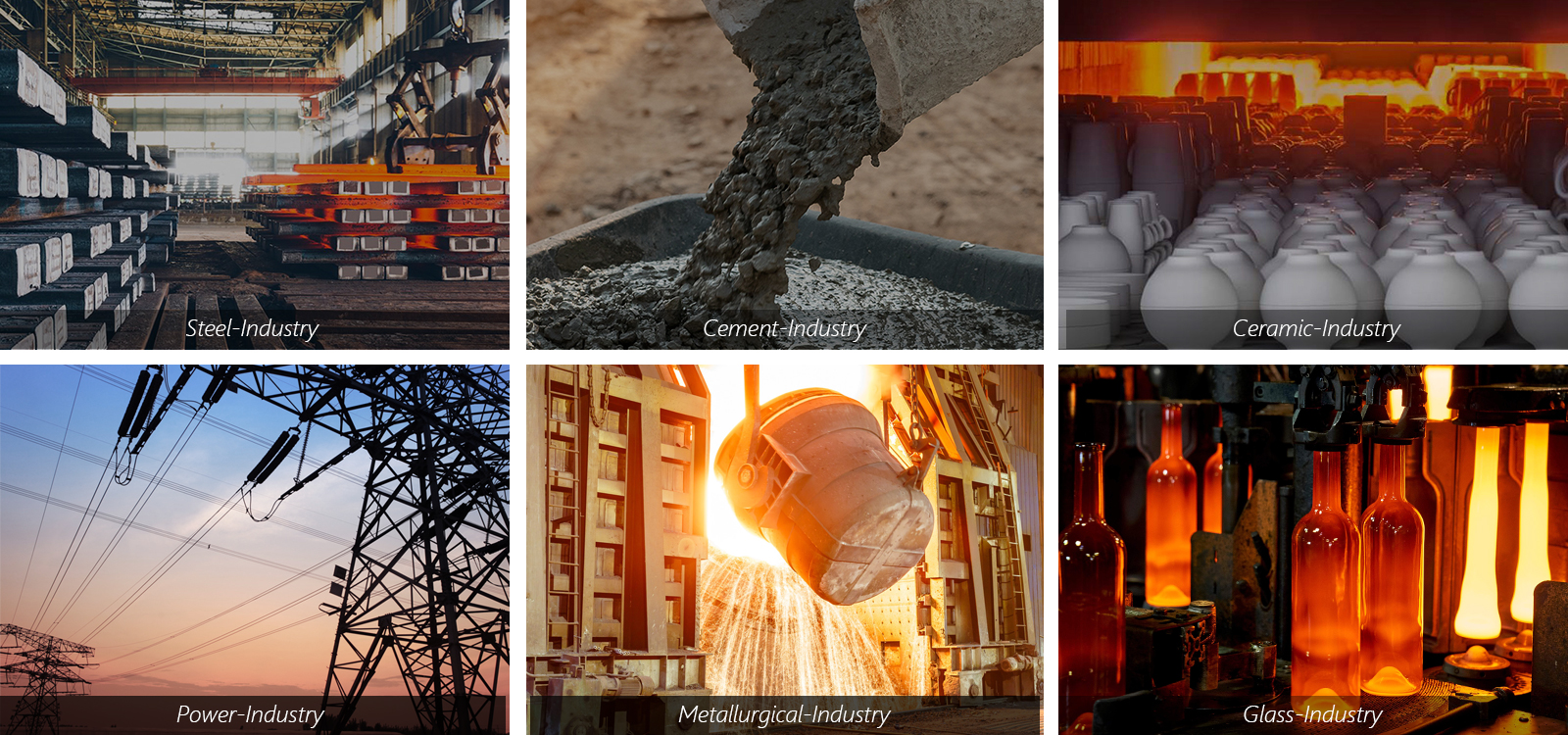

Fused Magnesium(FM) is a type of refractory material that is produced by the electric arc melting of caustic calcined magnesia, deadburned magnesia or raw magnesite in furnaces at temperatures in excess of 2750°C. It has a high melting point, excellent thermal shock resistance, and good chemical stability, making it a popular choice for use in a variety of industrial applications such as steelmaking, cement manufacturing, and glass production.

Kerui Fused Magnesium Technical Data Sheet

| Product | 氧化镁 | 二氧化硅 | Al2O3 | Fe2O3 | CaO | Loi | BD | 包装 |

|---|---|---|---|---|---|---|---|---|

| Name | (%) | (%) | (%) | (%) | (%) | (%) | (kg/cm3) | |

| FM94 | 94MIN | 2.5MAX | 0.6MAX | 1.0MAX | 2.0MAX | 0.3MAX | 3.4MIN | TON BAG (1.25) |

| FM95 | 95MIN | 1.5MAX | 0.6MAX | 1.0MAX | 2.0MAX | 0.3MAX | 3.4MIN | TON BAG (1.25) |

| FM96 | 96MIN | 0.9MAX | 0.2MAX | 0.8MAX | 1.2MAX | 0.2MAX | 3.45MIN | TON BAG (1.25) |

| FM97 | 97MIN | 0.7MAX | 0.2MAX | 0.8MAX | 1.2MAX | 0.2MAX | 3.48MIN | TON BAG (1.25) |

| FM98 | 98MIN | 0.5MAX | 0.15MAX | 0.5MAX | 1.0MAX | 0.1MAX | 3.48MIN | TON BAG (1.25) |

| Coarse Sizes | 1-15 mm, 3-15 mm, 5-15 mm, 3-8 mm, 5-10 mm, customizable | |||||||

| Small Fractions | 0-1 mm, 0.5-1 mm, 1-3 mm, 1-5 mm, 200 mesh, customizable | |||||||

| 包装 | 1.35 Ton Bags, customizable | |||||||

| Colour | Brown | 白色 | Large crystal | |||||

Fused Magnesia Production Process:

Magnesite (magnesium carbonate MgCO3) is converted into magnesia by the application of heat which drives off carbon dioxide (CO2), thereby converting the carbonate to the oxide of magnesium (MgO).

Fused magnesia is a high-purity material used in the production of refractory materials, ceramics, and other industrial applications. The production of fused magnesia involves several steps.

Raw Material Preparation: The raw material used in the production of fused magnesia is magnesite, a natural mineral. The magnesite is first crushed into small pieces and then calcined at high temperatures to remove impurities and water.

Fusion: The calcined magnesite is then mixed with coke and other additives and fed into an electric arc furnace. The furnace is heated to a temperature of around 3,000 degrees Celsius, causing the magnesite to fuse into a molten state.

Cooling and Solidification: The molten magnesia is then cooled and solidified by pouring it into molds or by spraying it with water. This process can take several days or even weeks, depending on the size and shape of the desired product.

Applications of Fused Magnesium

Fused Magnesium (FM) Application:

– High performance 镁碳砖 for steel industry,

– Fired refractory bricks for cement and glass industry,

– Heating elements industry

科瑞耐火材料实验室

科瑞拥有专业的质量检测实验室。高温再加热/荷重软化蠕变试验炉;耐火材料抗压/抗折强度试验台;耐火材料成分测试和检验平台;耐火材料物理/化学性能实验室。