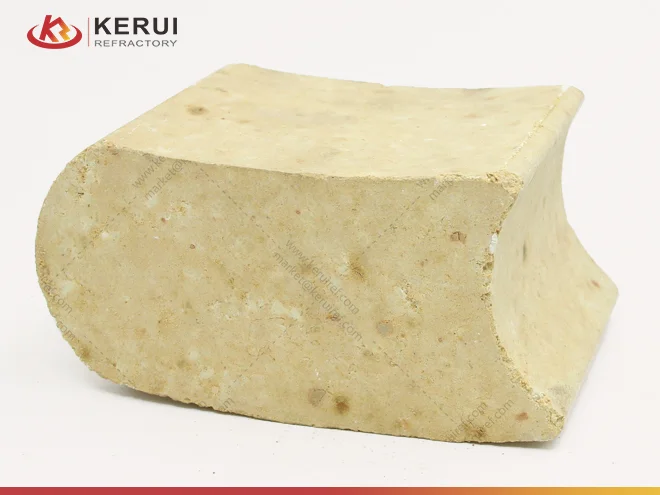

弧形耐火砖描述

弧形耐火砖是一种常见的半圆形设计异形砖,通常由高铝或粘土制成,具有良好的耐火性。它主要用于工业炉和锅炉等耐高温设备的内衬。弧形砖可承受 1400°C 或更高的温度。

由于弧形砖的特殊形状,它适用于圆形炉膛或弧形结构。它广泛应用于炼钢和陶瓷窑等高温作业。

凯瑞弧形耐火砖的技术数据

| 项目 | LZ-80 | LZ-75 | LZ-70 | LZ-65 | LZ-60 | LZ-55 | LZ-48 | |

|---|---|---|---|---|---|---|---|---|

| Al2O3、/% | ≥ | 80 | 75 | 70 | 65 | 60 | 55 | 48 |

| 表观孔隙率,% | ≤ | 21 | 24 | 24 | 24 | 26 | 22 | 22 |

| 冷压强度,兆帕 | ≥ | 70 | 60 | 55 | 50 | 45 | 45 | 40 |

| 0.2MPa 负载下的折射率,℃ | ≥ | 1530 | 1520 | 1510 | 1500 | 1430 | 1450 | 1420 |

| 永久线性变化,% | 1500℃*2h-0.4~0.2 | 1450℃*2h-0.4~0.1 | ||||||

弧形耐火砖的类型

弧形耐火砖可根据其材料、形状和用途进行分类。以下是主要的分类方法:

▶ Classification by Material:

1.Clay Refractory Bricks: mainly made of clay, suitable for environments with temperatures not exceeding 1300°C.

2.High Alumina Refractory Bricks: contain a higher proportion of bauxite, have high refractoriness, and are suitable for higher temperature applications.

3.Magnesium Refractory Bricks: use magnesium ore as raw material, have excellent corrosion resistance, and are often used in metal smelting.

4.Silica Refractory Bricks: mainly composed of silicon dioxide, suitable for acidic environments.

▶ Classification by Shape

1.Standard Curved Bricks: have a standard semicircular design and are suitable for general furnace structures.

2.Special Curved Bricks: include a variety of non-standard shapes, such as grooves or special angle designs, to adapt to specific furnace structures.

▶ Classification by Use

1.Curved bricks for blast furnaces: specially designed for blast furnace linings, withstand extreme high temperatures and chemical erosion.

2.Curved bricks for electric furnaces: used for electric furnace linings, emphasizing electrical insulation and thermal stability.

3.Curved bricks for cement kilns: Designed for special needs in the cement production process.