Kerui Kiln Furniture/Shelves For Sale

Keri Refractory offers two types of kiln furniture, including cordierite-mullite kiln shell and silicon carbide kiln furniture (OBSIC, SIC, SiSiC/RBSiC, RSiC, NSiC, SSiC). We also provide a variety of common sizes and customized products for more than 100 customers worldwide. Please choose the appropriate product according to the usage scenario:

1.Silicon Carbide Kiln Furniture/Shelves

Silicon Carbide Kiln Shelves is widely used in the ceramic and glass industries. It boasts high-temperature stability, wear resistance, and chemical stability. Primarily, it is used to support ceramic products in kilns, maintaining structural integrity at high temperatures and withstanding thermal cycling without deformation.

| Item | Silicon Carbide Kiln Shelves |

|---|---|

| Contents | SiC≥90%-99% |

| Bulk Density, g.cm-³ | 2.65-2.75 |

| Porositas Nyata, % | < 15 |

| Modulus of Ruture at 20°C, Mpa | 90-100 |

| Modulus of Rupture at 1200°C, Mpa | 100-110 |

| Hardness at 20°C, Kg/mm² | 1800-2000 |

| Fracture Toughness at 20°C, Mpa*M½ | 1.8-2.0 |

| Thermal Conductivity at 1200°C, W/m.k | 35-36 |

| Thermal Expansion at 20-1200°C, 1x10 */°C | 4.6 |

| Thermal Shock Resistance at 1200°C | Very good |

| Max.working Temperature | 1650°C |

The specific types of silicon carbide kiln furniture we can provide are as follows. If you have any questions or needs, please contact us to obtain the latest information and the best quotation!

- Length: 370-800mm;

- Width: 550-1000mm;

- Thickness: 11-20mm;

- Used in ceramic kilns (tunnel/shuttle), non-ferrous metal smelting furnaces, steel heating & heat treatment furnaces, glass kilns etc.

![]()

- Shape: Round and square;

- Custom Size: Available;

- Apparent porosity: ≤10-18%;

- Outer diameter: 142-1050mm;

- Inner diameter: 110-930mm;

- Overall height: 180-1320mm;

![]()

2.Cordierite Mullite Kiln Shelves&Furniture

Cordierite-Mullite Kiln Shelves/Furniture is highly favored in the ceramic industry due to its exceptional thermal stability, low thermal expansion, and high thermal shock resistance. This type of kiln furniture is primarily used to support ceramic products during firing, ensuring even heat distribution and reducing the risk of cracking or deformation. Its durable and lightweight nature allows for repeated use in high-temperature applications, thereby enhancing the efficiency and performance of the ceramic manufacturing process.

| Item | Cordierit Mullite Kiln Furniture |

|---|---|

| Mineralogy | Cordierite-Mullite |

| Al2O3, % | 37 |

| SiO2, % | 50 |

| MgO, % | 8 |

| Bulk Density, g/cm³ | 1.85 |

| Porositas Nyata, % | 28 |

| M.O.R. @ 20°C, Mpa | 15 |

| M.O.R. @1250°C, Mpa | 13 |

| C-16 .T.E.@ 25℃-1000, 10 K | 2.4 |

| Specific Heat @20°C, Kj/Kg.K | 1 |

| Thermal Shock Resistance, ★ | ★★★★ |

| Max Working Temperature, ℃ | 1320 |

The specific types of cordierite mullite kiln furniture we can provide are as follows. If you have any questions or needs, please contact us to obtain the latest information and the best quotation!

- L*W*T: (175-700)*(280-760)*(6-40);

- Customization: Supported;

- L*W*T: (175-700)*(280-760)*(6-40);

- Customization: Supported;

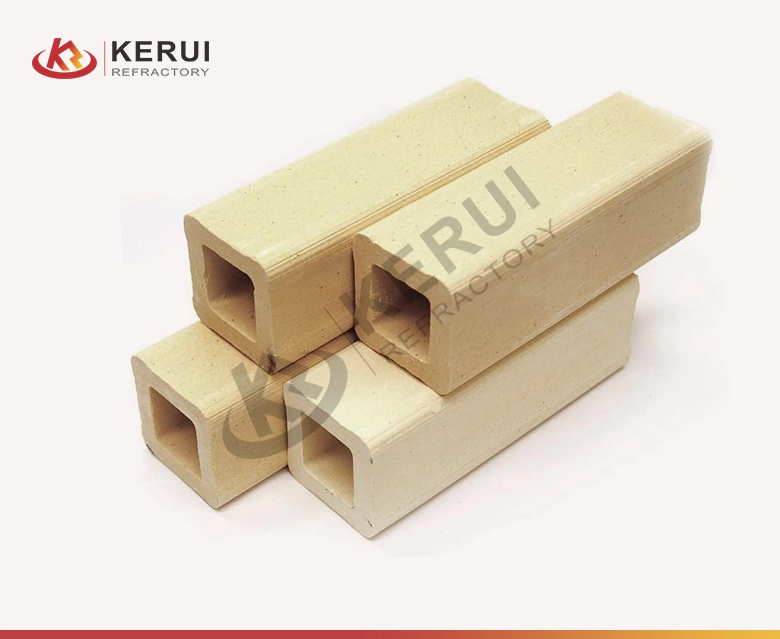

- Shapes: Square, round, and others;

- Types: Solid, hollow;

- Plate shapes, special shapes

- L-shape, Z-shape

- Shape: Round and square;

- Apparent porosity: ≤10-18%;

Aplikasi Furnitur Kiln

Kasus Pelanggan dari Kerui Refractory

Selain di daratan Cina, Kerui Refractory telah mengekspor produk ke lebih dari 50 negara dan wilayah di 5 benua di seluruh dunia, termasuk Asia, Eropa, Amerika, Afrika, dan Oseania.

Kami telah menerima pengakuan dan pujian yang tinggi dari pelanggan di seluruh dunia, dan terus menerima pesanan berulang dan rujukan dari pelanggan.

-

5Benua

-

50+Benua

-

1700+Benua

-

4500+Benua