·

·Sintered Magnesite

Sintered magnesia sand is divided into dead-burned magnesia, medium-grade magnesia and high-purity magnesia according to the preparation process and the mass fraction of magnesium oxide.

- w(MgO)≥/%: 90.0-97.7

- w(SiO2)≤/%: 0.3-4.8

- Volume density/g·cm3(≥): 3.18-3.40

Description of Sintered Magnesite

Sintered magnesia is generally made by directly calcining magnesite in a vertical kiln or a rotary kiln. The grade of sintered magnesia is calibrated by the mass fraction of MgO, and the highest grade can generally reach w(MgO)=98%. The main impurities in the raw materials are SiO2 and CaO, and the mass fraction of Fe2O3 is not high. Sintered magnesia is divided into dead-burned magnesia, medium-grade magnesia and high-purity magnesia according to the preparation process and the mass fraction of magnesium oxide.

Kerui Sintered Magnesite Technical Data Sheet

| Type | w(MgO)/% | w(SiO2)/% | w(CaO)/% | CaO/SiO2 molar ratio | Volume density/g·cm3 |

|---|---|---|---|---|---|

| MS98A | ≥97.7 | ≤0.3 | / | ≥3 | ≥3.40 |

| MS98B | ≥97.7 | ≤0.4 | / | ≥2 | ≥3.35 |

| MS98C | ≥97.5 | ≤0.4 | / | ≥2 | ≥3.30 |

| MS97A | ≥97.0 | ≤0.5 | / | ≥2 | ≥3.40 |

| MS97B | ≥97.0 | ≤0.6 | / | ≥2 | ≥3.35 |

| MS97C | ≥97.0 | ≤0.8 | / | / | ≥3.30 |

| MS96A | ≥96.0 | ≤1.0 | / | / | ≥3.30 |

| MS96B | ≥96.0 | ≤1.5 | / | / | ≥3.25 |

| MS95A | ≥95.0 | ≤2.0 | ≤1.6 | / | ≥3.25 |

| MS95B | ≥95.0 | ≤2.2 | ≤1.6 | / | ≥3.20 |

| MS93A | ≥93.0 | ≤3.0 | ≤1.6 | / | ≥3.20 |

| MS93B | ≥93.0 | ≤3.5 | ≤1.6 | / | ≥3.18 |

| NS90A | ≥90.0 | ≤4.0 | ≤1.6 | / | ≥3.20 |

| NS90B | ≥90.0 | ≤4.8 | ≤2.0 | / | ≥3.18 |

Types of Sintered Magnesite

1. Heavy burned magnesia sand

Heavy burned magnesite sand is magnesite, magnesite, seawater and brine magnesium hydroxide and other raw materials in 1600 ~ 1900 ℃ fully sintered and obtained the product. Sintered magnesite sand is sintered from magnesite in China. Using MgO mass fraction greater than 46.0% of magnesite lump ore and solid fuel blocks mixed, into the vertical kiln calcined magnesite sand production. The mass fraction of MgO is 89%~98%. Because of the high degree of sintering of magnesite sand, so sometimes also called dead burn magnesite sand.

The following table shows the technical index of typical heavy burned magnesium sand:

| IL | SiO2 | CAO | MgO | Al2O3 | Fe2O3 | Volume density/g·cm-3 |

| 0.27 | 3.87 | 1.86 | 92.48 | 0.62 | 0.90 | 3.16 |

The microstructure of heavy-burned magnesite sand is characterized by the main crystalline phase of magnesite, and the crystals are mostly rounded and irregularly granular. Its crystal size and shape depends on the purity of raw material and sintering temperature. Generally, the size of magnesite crystals in refired magnesite sand is small, between 20~60μm. The intercrystalline phase is often accompanied by silicate phase, the composition fluctuates between C3S-C2S-C3MS2-M2S. Magnesite a magnesite between the silicate phase of the colloidal bond is mainly. The intergranular open pores are more long.

2. Mid-grade magnesium sand

Using MgO mass fraction greater than 46.5% of magnesite, lightly burned by the reflection furnace, and then finely ground, mixed with water, ball pressed, mixed with solid fuel blocks into the vertical kiln calcined production of magnesium sand.MgO mass fraction of about 95%, also known as mid-range magnesium sand.

The following table shows the technical specifications of typical mid-grade magnesium sand:

| IL | SiO2 | CAO | MgO | Al2O3 | Fe2O3 | Bulk density/g-cm-3 |

| 0.50 | 1.95 | 1.58 | 94.63 | 0.34 | 1.00 | 3.17 |

The microstructure of middle-grade magnesite sand is characterized by the main crystalline phase of magnesite, the crystals are mostly rounded and irregular granular body, the crystal size is mostly between 50~100μm, the intercrystal is often accompanied by silicate phase, the composition fluctuates between C3S-C2S-C3MS2-M2S. Square magnesite a magnesite between the main silicate phase of the cementation bond between the crystals more open pores.

3. High-purity magnesium sand

The use of MgO mass fraction greater than 47% of magnesite, lightly burned to obtain a good high purity of lightly burned magnesium powder as raw material, by fine grinding, dry ball pressing, into the ultra-high temperature oil vertical kiln calcination production of magnesium sand MgO mass fraction of 96.5% to 98%, known as high purity magnesium sand.

The following table shows the typical high purity magnesium sand technical index:

| IL | SiO2 | CAO | MgO | Al2O3 | Fe2O3 | Volume density/g·cm-3 |

| 0.30 | 0.70 | 1.35 | 96.90 | 0.25 | 0.80 | 3.20 |

The microstructure of high purity magnesite sand is characterized by the main crystalline phase of magnesite crystal. The crystal size is between 30~100um. Intracrystalline, intercrystalline more round closed pores, pore size is mostly less than 10μm. intercrystalline silicate is less.

4. Seawater magnesium sand

China due to the magnesite ore reserves are abundant, for a long time metallurgical enterprises are mainly based on the production of magnesium sand from magnesite ore, and mainly low-grade magnesium sand. Using two-step calcination method, can produce high-purity magnesium sand with purity close to 97%, so far it is still difficult to produce ultra-high purity magnesium sand not less than 99% with heavy firing method.

Therefore, from the actual situation in our country, the use of a single physical method to produce a large number of high-purity magnesium sand from the ore more than 98%, especially not less than 99% of the ultra-high-purity magnesium sand is still more difficult. And from seawater, especially from the brine production of high purity and ultra-high purity magnesium sand is obviously much easier, it has more advantages than from magnesite production of high purity magnesium sand. Seawater magnesium sand MgO mass fraction up to 99.5%, the general seawater magnesium sand is also in 98% to 99%.

The following table shows the typical technical specifications of seawater magnesium sand:

| IL | SiO2 | CAO | MgO | Al2O3 | Fe2O3 | Volume density/g·cm-3 |

| 0.25 | 0.23 | 0.53 | 98.85 | 0.03 | 0.11 | 3.20 |

Typical microstructure characteristics of seawater magnesite sand is the main crystalline phase magnesite crystal size uniform, pure texture, material multiple grain boundaries and microporous structure. Magnesite crystals usually in 30-50μm, intercrystalline silicate phase less, more direct bonding between crystals, intracrystalline, intercrystalline more closed pores, pore size uniform, pore size mostly in 5μm or less.

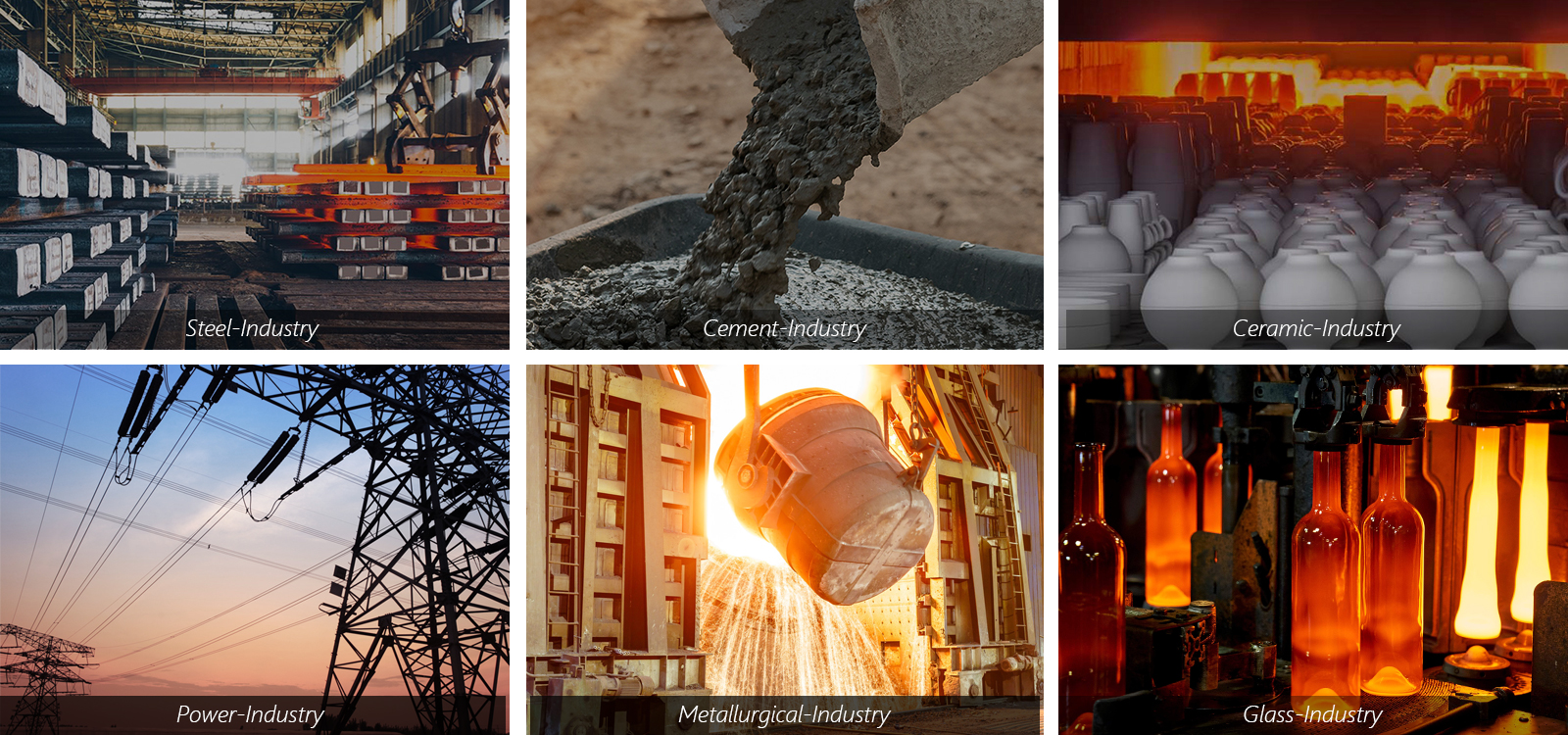

Applications of Sintered Magnesite Sand

In the steel industry, sintered magnesia is used to make refractory bricks and furnace linings to resist the high temperatures and chemical corrosion during the steelmaking process. In non-ferrous metal smelting, sintered magnesia can protect equipment from the harsh molten metal environment. For refractory coatings and castables, sintered magnesia can improve heat resistance and mechanical strength. In addition, sintered magnesia can also be used to produce advanced ceramics and abrasives, taking advantage of its hardness and stability. Its excellent thermal and chemical properties make it an indispensable material in high-temperature industrial processes, ensuring the durability and operating efficiency of equipment.

Laboratoire de Kerui Réfractaire

Kerui dispose d'un laboratoire professionnel d'inspection de la qualité. Four d'essai de fluage de réchauffage/adoucissement à haute température ; banc d'essai de résistance à la compression/flexion pour les matériaux réfractaires ; plate-forme d'essai et d'inspection de la composition pour les matériaux réfractaires ; laboratoire des propriétés physiques/chimiques pour les matériaux réfractaires.